For almost 30 years, Galdi has been dedicated to providing value-added solutions for filling machines, continuously improving and evolving. We specialize in the packaging of milk, dairy products, fruit juices, and liquid eggs in Gable Top cartons, ensuring customer satisfaction through long-term relationships.

Continuous innovation drives our work as we strive to develop machines that are increasingly efficient, productive, and sustainable, meeting the highest standards in the industry.

Galdi’s cutting-edge technology: a new era in filling machines

Our customers choose us for multiple reasons, ranging from advanced technology and user-friendly machines to the exceptional care we dedicate to their needs. Partners like Tirlàn and Newburg Egg showcase how shared goals of efficiency and environmental responsibility translate into high-value production results.

Here are the key factors that define our manufacturing approach.

Ease of use and Ergonomics: the core of Galdi’s automated filling machines design

Our production focuses on simplifying and automating operations by developing machines that prioritize ease of use and ergonomic design. These innovations significantly reduce production complexity and time while enhancing overall efficiency.

A prime example is the latest-generation Galdi RG480 filling machine, designed with exceptional usability in mind:

- Double-line half-gallon capacity (95×95 mm section) with an output of 10,000 cartons/hour

- Ideal for ESL dairy products, fruit juices, and plant-based beverages distributed via the cold chain

We proudly call it an “inexperienced operator-proof machine” as minimal training, combined with its wizard mode, allows operators to optimize performance effortlessly.

Another highlight is the Galdi RG270, which reflects our commitment to innovative design. Its features include:

- A large windowed area for enhanced visibility and process control

- Simplified component disassembly for efficient maintenance

By adhering to Ergonomic Design principles (focused on operators) and Design for Maintenance (focused on technicians), Galdi delivers solutions that enhance usability, accessibility, and reliability in every aspect of machine operation.

Sales support for filling machines

With its headquarters in Delaware and a warehouse in New Jersey, Galdi Inc. serves as the primary point of contact for our overseas customers. Our U.S.-based team provides comprehensive support for Galdi packaging systems across the United States, Canada, the Caribbean, and Central and South America.

Thanks to a well-coordinated and agile team, Galdi ensures top-tier maintenance services and efficient spare parts management in the region.

Local and Remote assistance

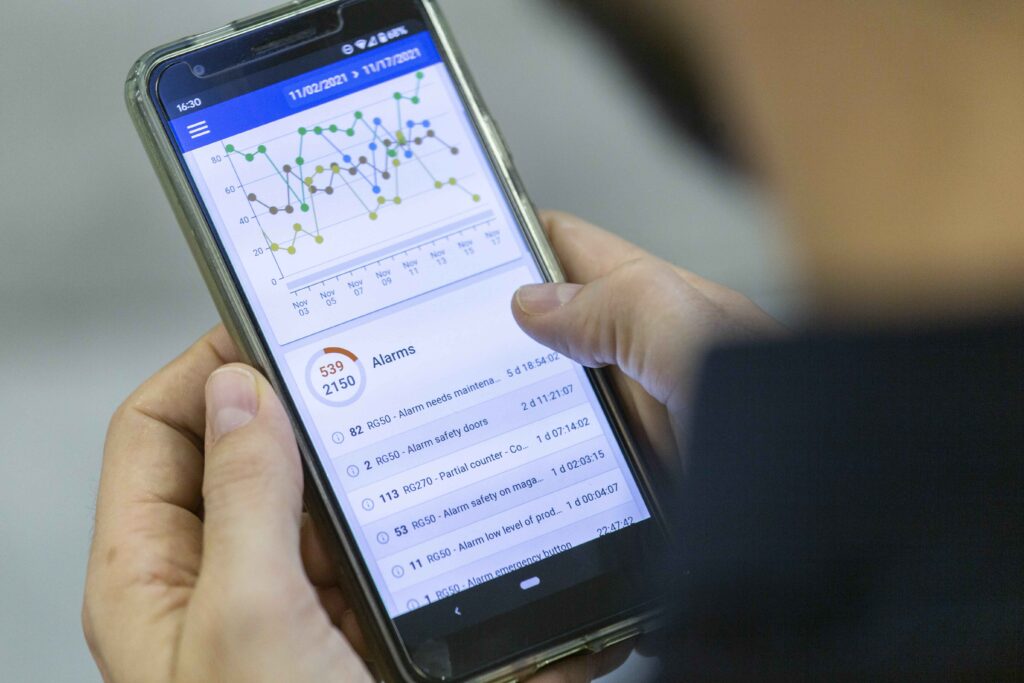

With the dedicated support of our U.S. team, we offer customers a wide range of services and competitive advantages. Additionally, our packaging machines are equipped with smart systems that enhance productivity and streamline maintenance:

- Operator and maintenance support: smart features assist staff in managing production and maintenance autonomously.

- Real-time remote assistance: video support and remote troubleshooting help resolve issues quickly.

- Advanced diagnostics: data collection and alert analysis ensure faster issue identification and resolution.

- Automatic configuration: new components can be set up remotely or automatically.

Spare parts management

Our New Jersey warehouse guarantees the constant availability of spare parts and swift deliveries. Additionally, customers benefit from the Galdi e-Portal, a digital spare parts platform offering:

- 3D component drawings for precise selection

- Access to purchase history

- Real-time availability and lead-time information

This seamless integration of local expertise, remote assistance, and advanced technology ensures our customers experience efficient, reliable, and responsive service.

Optimizing TCO: sustainable and efficient solutions for your filling machine

Galdi focuses on helping customers reduce their Total Cost of Ownership (TCO) by prioritizing energy efficiency, sustainability, and waste reduction throughout the lifecycle of its filling machines.

Advanced automation and next-generation digital native machines, including automatic filling technologies, enhance production efficiency, lower operational costs, and optimize energy use while reducing waste. Predictive maintenance and remote support further ensure reliable performance and resource efficiency over time.

Maintenance and spare parts management plays a crucial role in Galdi’s TCO reduction strategy. Our company provides operator training, tailored maintenance plans, and durable, high-quality spare parts that maximize efficiency.

Galdi’s commitment to sustainability is embodied in its Eco Design philosophy and continuous research efforts. Innovations like the RG280 machine demonstrate significant reductions in energy consumption, water usage, and food waste. By integrating cutting-edge technologies and sustainable practices, Galdi delivers cost-effective and environmentally responsible packaging solutions that meet the needs of a dynamic market.

Comprehensive training for optimal machine performance

At Galdi, we believe training is essential for enhancing troubleshooting and problem-solving skills while ensuring that filling machines consistently deliver peak performance. To meet this goal, we provide online training solutions for operators and maintenance technicians, offering the same depth and quality as in-person courses. These training programs feature:

- Flexible scheduling tailored to the customer’s availability.

- Custom content aligned with participants’ prior knowledge, available in English or French.

- Specialized modules, including hygiene procedures to maintain food safety standards.

We have also expanded training opportunities for service engineers and machine operators, focusing on critical topics such as hygiene best practices to ensure food safety in the filling area

Every day, Galdi fosters an inclusive and dynamic work environment, where each team member is encouraged to reach their full potential and contribute to our collective success. We believe that continuous experimentation is key to enhancing our products and services. By constantly expanding our knowledge and sharing it, we are committed to delivering the best in filling machines.

Our ongoing achievements demonstrate our determination to not only meet but exceed expectations, consistently improving with each step.