At Galdi, our approach to pre-sale and after-sale consultancy services is centered around delivering highly efficient technology solutions for the entire production line, including newly conceived end-of-line packaging machines. This innovative design reflects our commitment to excellence and is further enhanced by our acquisition of Artema Pack, renowned for its expertise in end-of-line packaging machines.

In the competitive U.S. market, we understand the importance of providing tailored solutions that meet the specific needs of food producers. Our integrated systems not only boost productivity but also ensure that the packaging process aligns seamlessly with the quality standards expected by consumers. With the increasing demand for sustainable packaging, our offerings also include food paper containers, designed to meet both environmental considerations and consumer preferences.

We are particularly excited about our new approach to food packaging machines, which emphasizes innovation and flexibility. This fresh perspective allows us to create packaging solutions that are not only efficient but also adaptable to various products and formats. By incorporating advanced automation and user-friendly interfaces, we aim to streamline the packaging process, reduce waste, and enhance overall operational efficiency. Our goal is to provide comprehensive consultancy that empowers businesses to improve efficiency, reduce costs, and enhance product quality, all while ensuring compliance with industry regulations.

As we continue to expand our presence in the United States, we remain committed to innovation and customer satisfaction, helping our clients navigate the complexities of the food packaging landscape. Whether you are looking to upgrade your existing systems or implement new solutions, Galdi is here to assist you every step of the way.

Galdi and its American subsidiary, Galdi Inc, are industry leaders in primary packaging solutions, offering not only advanced filling machines but also complete packaging systems. This includes a full suite of end-of-line solutions, such as wrap-around packaging machines, made available through our partnership with Artema Pack.

The Importance of a Holistic View in End-of-Line Packaging Machines

Investing in a state-of-the-art filler is ultimately futile if the end-of-line phase is neglected. It is essential to recognize that the packaging process is not complete without a thorough consideration of the final packing stage. Conversely, concentrating solely on product packaging while disregarding the intricacies of the final packing process can lead to significant inefficiencies and operational challenges.

Effective packaging demands an integrated approach that harmonizes with both the characteristics of the packaged product and the specific requirements of the production process. This comprehensive strategy ensures that production, quality, and efficiency standards are consistently upheld throughout the entire packaging line. By aligning each phase of the process, manufacturers can optimize workflow, reduce waste, and enhance overall productivity.

Furthermore, the importance of end-of-line packaging extends beyond mere functionality; it plays a critical role in the distribution phase as well. Properly executed end-of-line packaging is vital not only for ensuring product safety during transport but also for enhancing brand perception in the eyes of consumers. A well-packaged product conveys professionalism and attention to detail, which can significantly influence customer satisfaction and loyalty.

Integrated Fillers and Food Packaging Machinery

The integrated design of the entire production line offers significant advantages that enhance efficiency and productivity:

- Faster and safer installation and setup: the streamlined design allows for quicker assembly and configuration of the machinery, reducing downtime and ensuring a safer working environment for operators.

- Optimal use of the production area: by integrating filling and packaging processes, the layout maximizes the available space, allowing for a more organized and efficient workflow.

- Improved MME and OEE stability in both the short and long term: the integration helps maintain stable Machine Mean Efficiency (MME) and Overall Equipment Effectiveness (OEE), ensuring consistent performance and reliability over time.

- Coordinated filling and packaging operations: when filling and packaging machines work together seamlessly, it minimizes delays and enhances the overall speed of production, leading to higher output.

- Enhanced integration among machine systems: a cohesive system allows for better communication between different machines, facilitating smoother operations and reducing the likelihood of errors.

When filling and packaging machines operate in harmony, the dreaded sound of the downtime alarm becomes a thing of the past for production managers. With the acquisition of Artema Pack technologies, we are excited to provide our clients with even greater opportunities for success, ensuring they can fully leverage these integrated solutions for optimal performance.

Galdi and Artema Pack End-of-Line Packaging Machines

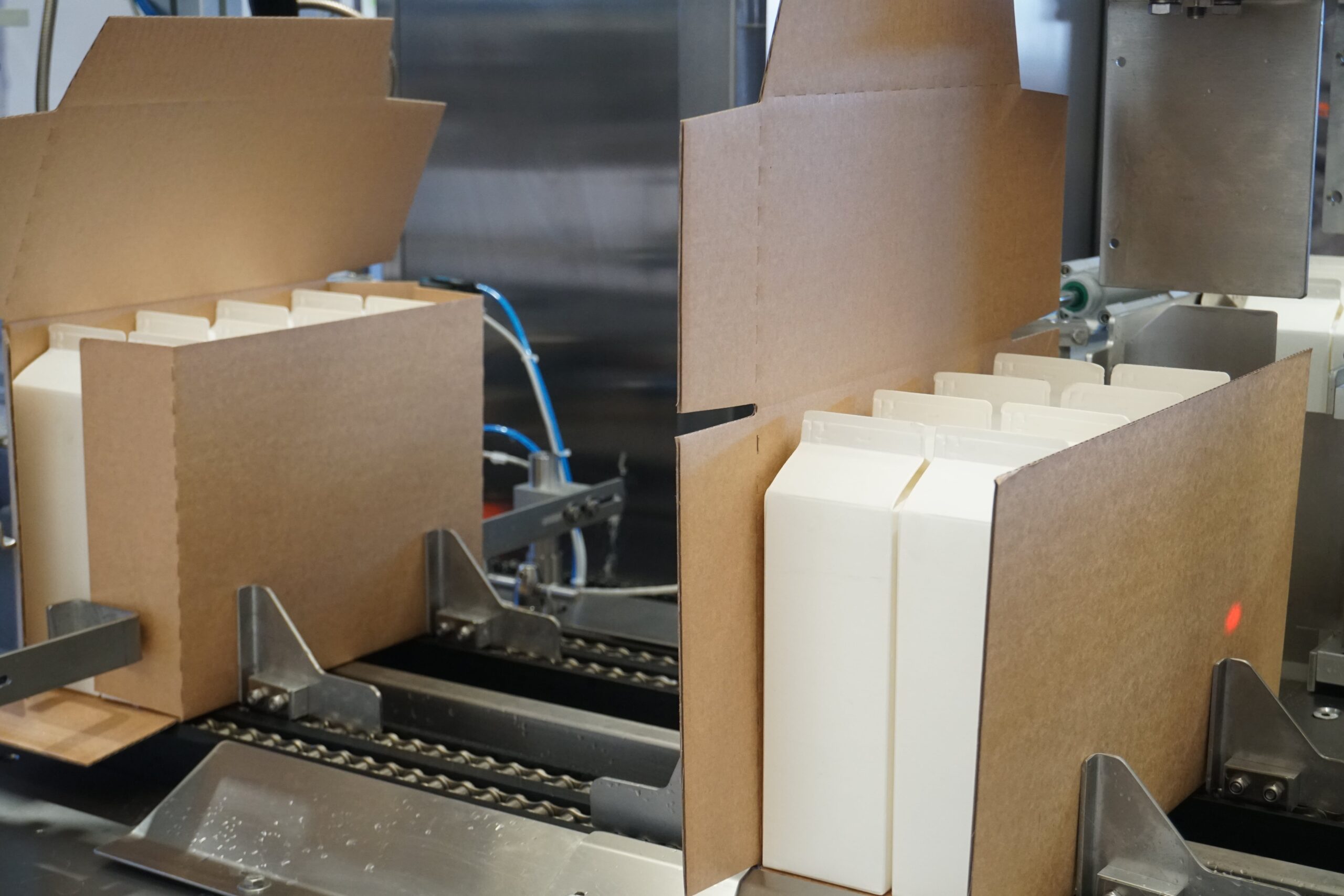

When considering a packaging machine, several aspects must be integrated, including the previously mentioned features, while also emphasizing maximum simplicity and optimization, particularly from a sustainability perspective. With over 30 years of experience, Artema Pack has developed a comprehensive range of end-of-line packaging machines and systems tailored to various products and packaging types, such as Gable Top milk cartons, fruit juice bricks, and dry foods.

Each machine is meticulously designed to simplify and optimize operations, from shrink film wrappers to wrap-around and American Box case packers. This shared commitment to efficiency is what connects Artema Pack’s packaging machines with Galdi’s automated filling machines, providing cost-effective and time-saving solutions that significantly enhance productivity.

By integrating these advanced technologies, we ensure that our clients benefit from streamlined processes that not only meet their operational needs but also align with modern sustainability goals. Together, Galdi and Artema Pack are dedicated to delivering innovative packaging solutions that drive success in the food industry.

Galdi: Your Filling Process Consultant – What Are Our Next Goals?

In an increasingly innovative market where performance must be continuously balanced with sustainability, Galdi and its subsidiary, Galdi Inc., are committed to moving forward and staying at the forefront of the industry in the U.S. The design of modern end-of-line packaging machines cannot be separated from the need for efficiency and sustainability. The expertise gained from our acquisition of Artema Pack enhances the process knowledge that Galdi has developed over the years. Today, we can provide comprehensive advice and technology solutions for the entire production line.

Our services are tailored to food producers looking to establish efficient processes from the very beginning, as well as to established plant owners seeking to improve their filling and packing operations. For more information about our offerings and how to optimize your packaging processes, please do not hesitate to contact us. We will respond promptly.